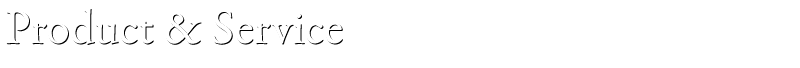

A device installed in every part of a pipeline to adjust the flow of fluid (flow rate).

While it is often recognized as a type of valve, it displays the following differences.

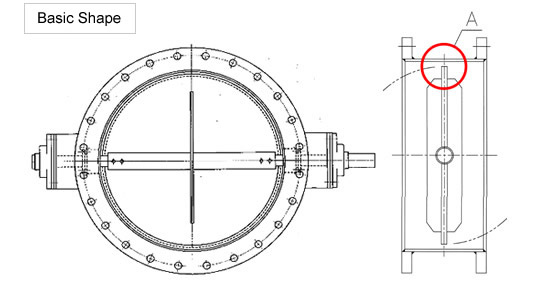

– While there are no leaks when a valve is fully closed,

there are leaks when a damper is fully closed.

– A damper is compatible with many shapes (large opening diameter, angled type etc.)

and specification conditions (high temperatures etc.) with which a valve is not.

– A valve is a standard (mass-produced) part, while dampers are custom designed and manufactured,

and so it is possible to serve the customer’s needs in a flexible manner.

1. Flow Rate Control

2. Shielding

(blocking) fluid by fully closing or opening

3. Switching fluid flow

– Working Pressure 1. 0kPa – 10kPa

– Working Temperature Ambient Temperature – 900°C

– Applicable Fluid Gas/Exhaust Gas/Dust

Open Type |

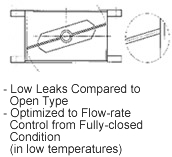

Step Sheet |

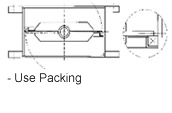

Sheet Packing |

||

|

|

|

||

15° Closeout |

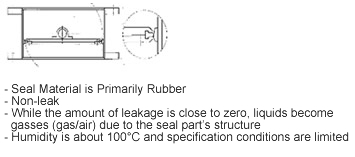

Closed Type |

|||

|

|

|||

| Damper Models | Basic-model Symbol (proposed) |

|---|---|

| Open Type (Standard Type) | ST Type |

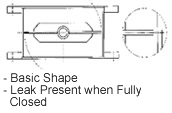

| Step Sheet Type (Back Sheet Type, Metal Touch Type) | B Type |

| Sheet Packing Type (Soft Sheet Type) | S Type |

| Spring Sheet Type | SM Type |

| 15° Closeout Type | AST Type |

| Closed Type (Butterfly Valve) | BV Type |